Expect Distribution has invested heavily over the past 10 years within its resources, infrastructure and fleet in developing its specialist services. Our Pharma team have over 30 years' experience of dealing with pharma products both from a storage and a distribution perspective.

This is how we can bring you so much extra value; allowing you to deliver strategic competitive advantage rather than simply being an unavoidable operational cost. Our solutions which are quality driven range over storage and delivery of medicinal products, medical devices, excipients and API's to manufacturers, retailers and distributors for both human and animal products.

Whether modelling and executing complex solutions or providing simple regional operations, we have the logistics and industry expertise to support healthcare supply to the retail and wholesale sector across the UK with pallet and consignments dealt daily.

Quality Management

A major integral support factor to our storage, supply and distribution processes is our Quality Management System which works consistently with Good Distribution Practice standards. Expect Distribution are fully licensed by the MHRA with Wholesale Distribution Authorisation (Human), Wholesale Distribution Authorisation (Veterinary) licences and API registrations for multiple sites. Our accredited licences apply to our fully secured 24hr surveillance/CCTV Head Office Premier Point, Bradford site, plus API registrations at Premier Point and an additional site also located in bradford. In total, we have three sites extending to over 500,000 sq ft and housing 60,000 pallets.

Dedicated Pharma Team

We have two onsite dedicated Responsible Person/Wholesale Dealer Qualified Persons supported by other GDP trained team members. They are directly involved with the MHRA and Veterinary Medicines Directorate and are the main point of contact for our regular inspections by our customers and MHRA inspectors of our storage, distribution and the Quality Management System (QMS).

Temperature Controlled Services

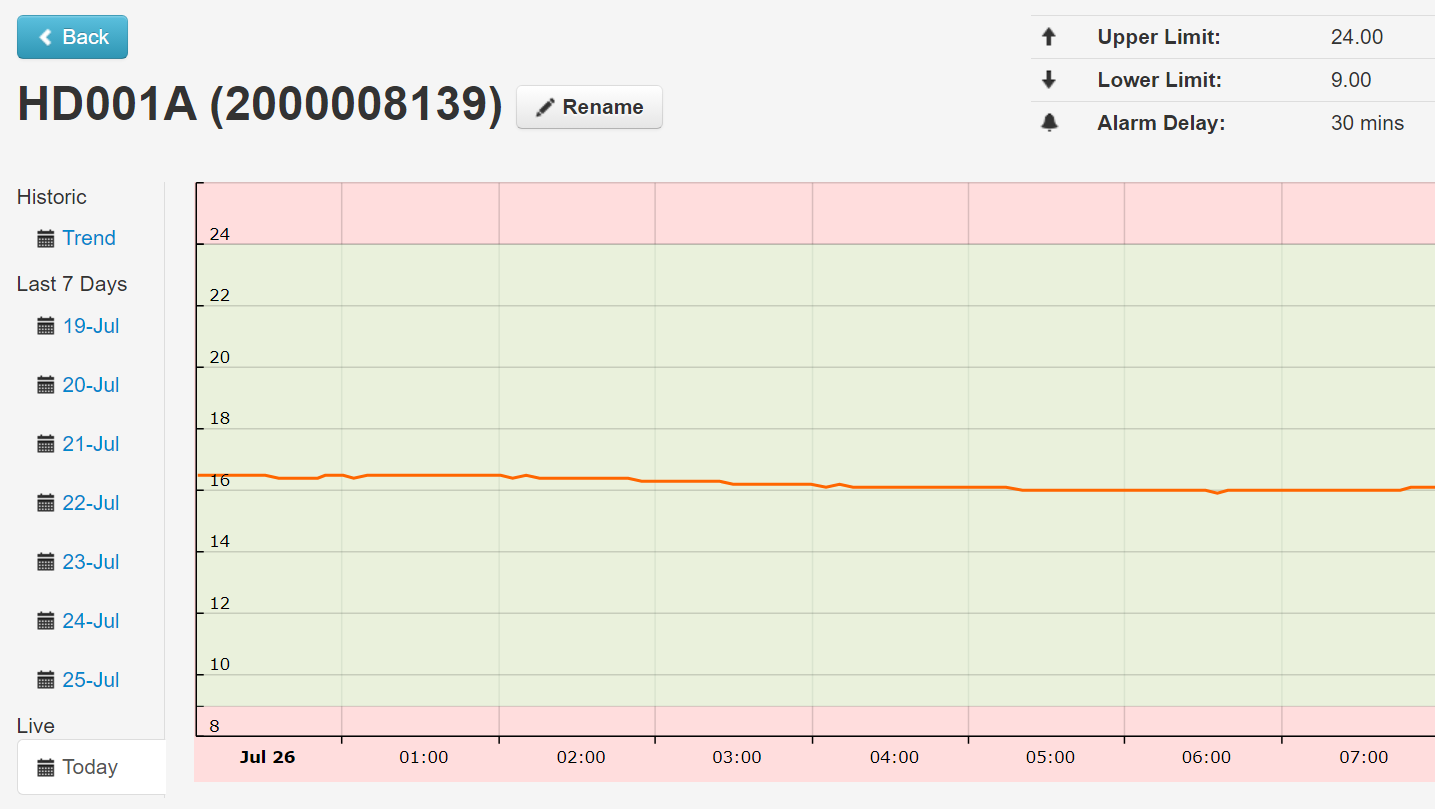

We provide accurately monitored temperature controlled services, across our Pharma storage and delivery vehicles, delivering finished medicinal products, medical devices, excipients and API's to destination whilst following Good Distribution Practice (GDP) guidelines.

First, we identify your needs; as we know each customer has specific requirements for handling your product, putting together a thorough analysis of your business, we then design a solution tailored to your needs. We develop these bespoke solutions, to protect the integrity of your pharmaceutical products in transit.

Our Pharma investment includes dedicated temperature-controlled trailers and warehouses. Our transportation and warehouse solution ensures safe and efficient transportation and storage for our clients in the healthcare industry and carried out to GDP standards. These controlled temperature facilities allow us to offer warehouse capacity for a range of pharma products. Should you have products less sensitive to temperature variations, we utilise our trusted Palletline network/courier services. All inventory is recorded and controlled by our warehouse management system and this tracks stocks from receipt to dispatch of goods and records all relevant information such as receipt of goods from the supplier, batch details, expiry dates, internal movements and the despatch of goods. All products are checked using RF scanners and barcodes within the warehouse environment on both inventory and storage areas.

Real time traffic management

Our traffic management system allows real time tracking of goods that have left for delivery to customers which are fully-validated and temperature-mapped to ensure full product safety. Our team uses GPRS systems to track our entire fleet throughout the UK, resulting in reliable temperature-assured and timely deliveries. All deliveries are planned and tracked using specialist planning and telematics software. Vehicles are fitted with enhanced hardware that can offer updates in minutes on deliveries and provide optimal route plan to drivers using live traffic to reduce down time. Drivers are furnished with the latest devices that have constant communications with the traffic office, ensuring complete continuity and ensuring control of the products and regulated temperatures at all times.